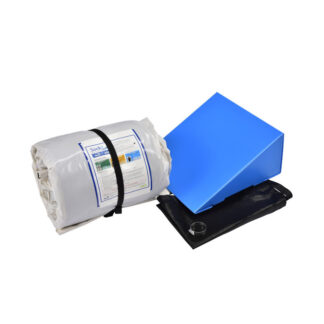

Trident Oil Water Separators

Made in the UK

Need help choosing a product?

0800 0370 899Product No: 0436

For effective removal of petrol, diesel and oil from water on construction sites.

Trident Oil Water Separators cut oily water disposal costs by 75%.

Available for Hire – enquire now for more details

Please get in touch if you want to know more

Trident Oil Water Separators

- Product Information

- Delivery Information

For effective removal of petrol, diesel and oil from water on construction sites.

Trident Oil Water Separators cut oily water disposal costs by 75%.

Key features

- Simple operation

- Low maintenance

- 15m3/hr throughput

- Filters oil to less than 5 ppm

- Meets discharge requirements

The Trident Oil Water Separator efficiently meets the needs for separating oil from water on construction sites. Using a four stage filtration process the static or trailer mounted unit can be operational within fifteen minutes of deployment and is capable of handling 15m3/hr throughput. The oil and water mix is filtered down to less than 5 parts per million meeting discharge requirements (subject to consent)

Use:

- In ground remediation

- To separate the oil from water contained within pits or ditches

- To remove oil from bunds and interceptors

- To clean up oil spills

The cleaned water may be recirculated back to source (pending discharge consent) whilst the recovered oil can be sold, reused or disposed of via a waste management contractor at a significantly reduced cost.

Operation:

The oily water mix is pumped via a peristaltic pump into the main inlet and gravity fed through the following four separation chambers:

- Chamber 1 – Sludge settling and debris screening

- Chamber 2 – Coalescing filter with adjustable weir and oil outlet

- Chamber 3 – Polypropylene filter

- Chamber 4 – Final carbon polishing filter

Each chamber has its own independent discharge ball valve with camlock connector for ease of use, cleaning and maintenance.

Performance criteria:

The following is a guide to optimum performance when the Separator is operated correctly, observing correct procedures.

- It is essential that the unit is operated with an oil/water mix. This is a prime requisite for the operation of the coalescer stage. For optimum performance there should be no less than 50% water input. A very high percentage of water input does not adversely affect correct operation or significantly affect filter life.

- The recommended maximum throughput capacity depends on many factors such as the viscosity, temperature, solubility detergent content etc. A guideline to maximum recommended throughput is as follows: –

Lube oil – 8 Cu m/hr

Crude oil – 15 Cu m/hr

Gas oil/diesel – 15 Cu m/hr

Petrol – 18 Cu m/hr

Note:

a) Performance with Lube Oil limited due to detergent content.

b) The separator is not recommended for use with cutting oils or mineral oils due to the high emulsification factor of these oils.

c) If in doubt as to the best throughput rate, run at a slow rate.

Construction:

Robust steel construction for long life under arduous environmental conditions. Surface coating two part epoxy coating. The static version is skid mounted. The trailer version is a full road going unit compliant to EC directives. Suspension incorporating four wheels and fitted with auto reverse braking. Full EEC 12v electrics. Fitted with 50mm ball coupling and jockey wheel. Four heavy duty adjustable and locking corner stands allow use on uneven ground. Supplied with 3 metres of 3 inch discharge hose and connector. The static version is skid mounted.

This product is typically made to order and has an average lead time of 3 to 4 weeks. Upon receipt of your order we will contact you with an order confirmation detailing the delivery date. If you require this product by a specific date please be sure to include this information on your order.